10+

years of

experience

About Us

Our Services

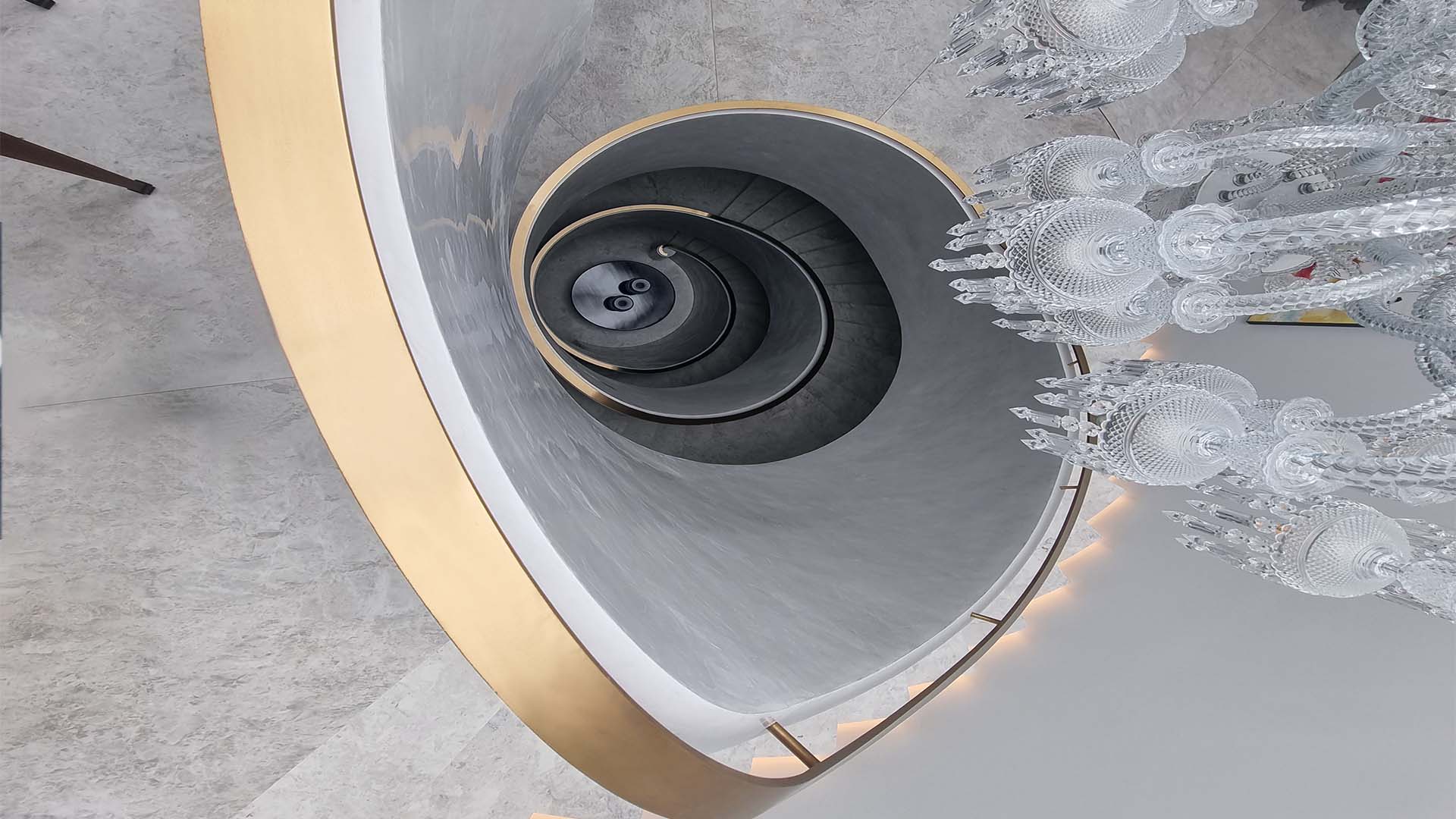

Medve Design Pty Ltd offers comprehensive support for your projects, from the initial design and fabrication stages through to the final installation. Our in-house workshop boasts a full array of machinery, enabling us to meet ultra tight deadlines while maintaining exceptional results.

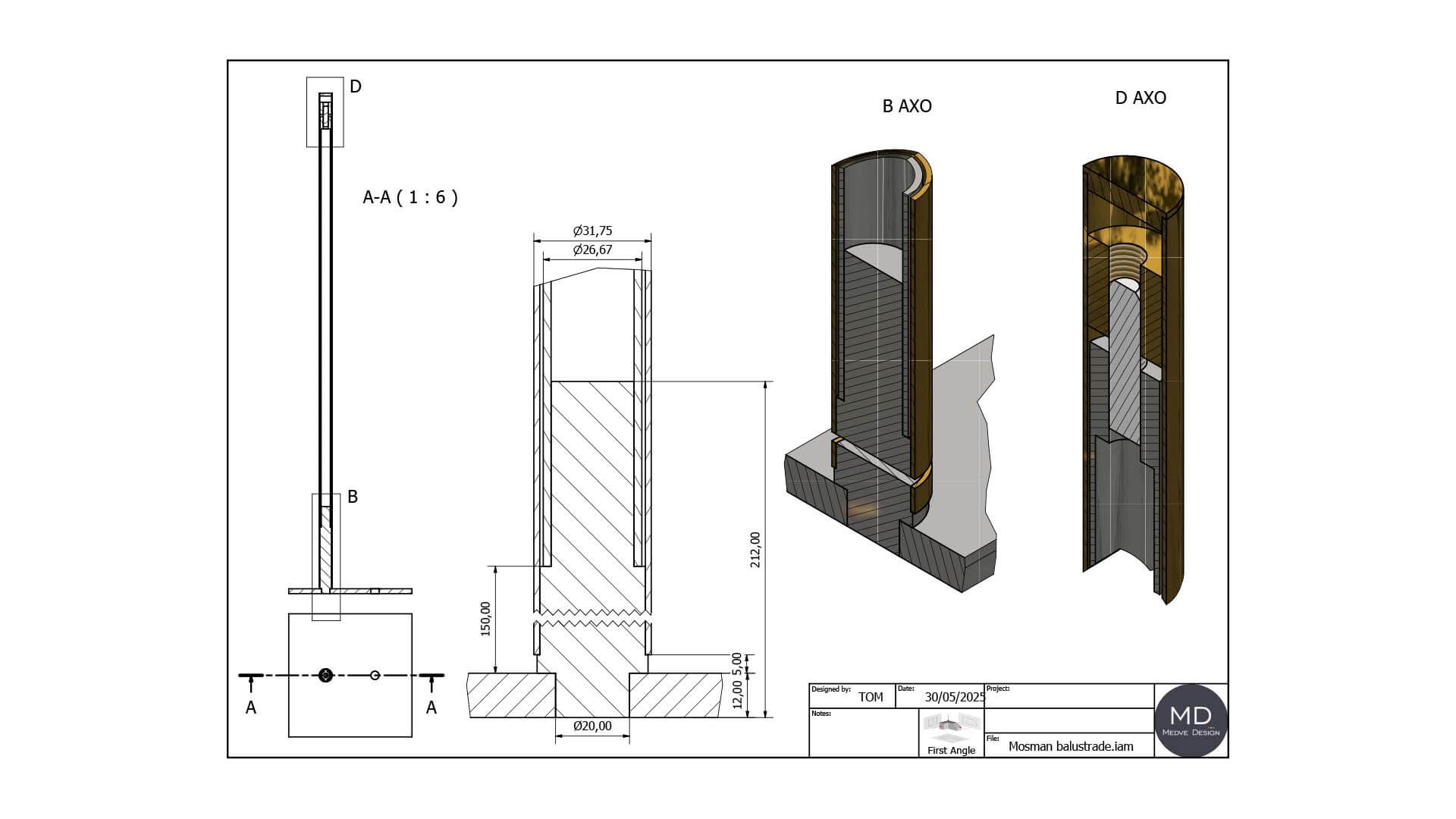

3D CAD Designs, Models and Drafting

Based on architectural drawings or sketches using Autodesk Inventor software, we produce 3D models and shop drawings.

We can simulate complex moving mechanisms with the 3D models. We can cooperate with Engineers for sign-off.

LASER Cutting

4x2m 6kW Fibre laser machine. We can cut:

- Brass, Copper up to 12mm

- Stainless steel up to 25mm

- Aluminium up to 16mm

- Mild steel up to 30mm

Welding

- Laser Welder: 3kW dual wire for Brass, Stainless Steel, Aluminium, Mild Steel

- TIG and Stick welders up to 350A AC-DC

- MIG welders up to 350A

- Silver soldering, soft soldering

Bending

250 T 4m 7-axle CNC press brake with different tools for tight bends and radius bends. We also perform grooved bends to reduce the outside bending radius.

3D Bending

For highly complex bends that cannot be achieved by machine, our skilled team offers manual, template-guided 3D bending.

Router

3x1.5m CNC router capable of routing 3D surfaces on Brass and Aluminium.

Lathe

2 Centre Lathes for precision work.

Milling

2 Industrial Turret Milling machines for precise and versatile operations.

Ageing, Coloring, Patina

We can finish Brass and Copper in a full range of tones, from natural gold to black. Color matching with existing finishes is also available.

We also provide chemical blackening for Stainless and Mild Steel, with lacquer options including nano-particle, 2K, traditional acrylic (matte, satin, gloss), heat-resistant up to 500°C, and beeswax finishes.

Miscellaneous

Our workshop includes rolling machines for various sections and sheets, drills, polishing and linishing machines, spot welders, welding benches, and more.